CNC Machining Services

As a trusted machining manufacturer and CNC machining compay, our dedication to delivering exceptional solutions sets us apart in the industry.

Our Capabilities

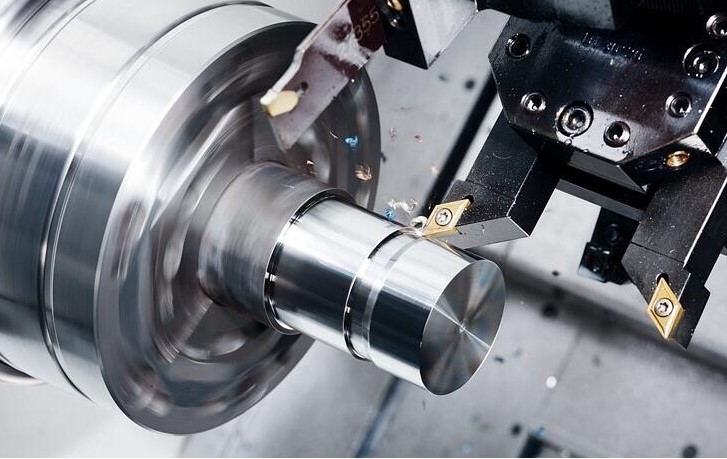

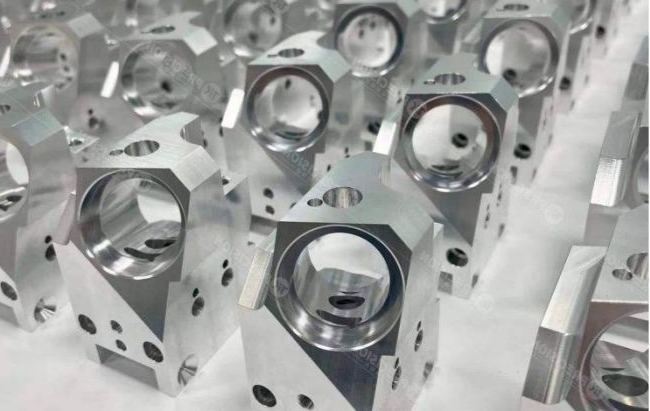

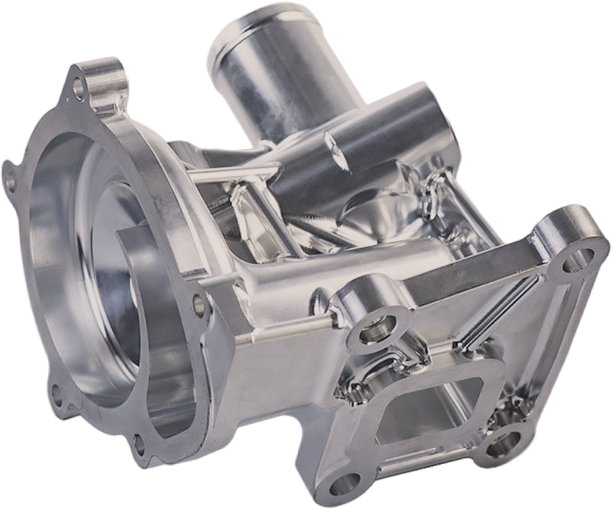

We provide top-notch CNC machining services as your comprehensive solution. Our skilled team and advanced equipment ensure precise and efficient results for milling and turning projects, whether it’s prototypes or mass production. Contact us today for your requirements.

Get Professional CNC Machining Services – Specializing in 3-axis 3+2-axis, 5-axis Milling.

Experience Precision and Efficiency with our 2-axis Turning and Multi-axis Turning Services.

Size Limitations and Precision Tolerances

3-axis and 3+2-axis Milling | 5-axis Milling | |||

Imperial units | Metric units | Imperial units | Metric units | |

Maximum Dimensions | 64 x 32 x 20 in | 1625 x 812 x 508 mm | 42 x 24 x 20 in | 1066 x 609 x 508 mm |

Minimum Dimensions | 0.25 x 0.25 x 0.04 in | 6.35 x 6.35 x 1.02 mm | 0.25 x 0.25 x 0.04 in | 6.35 x 6.35 x 1.02 mm |

Tolerances* | +/- 0.005 in | +/- 0.127 mm | +/- 0.005 in | +/- 0.127 mm |

2-axis Turning | Multi-axisTurning | |||

Imperial units | Metric units | Imperial units | Metric units | |

Maximum Dimensions | D 50 x 60 in | D 1270 x 1524 mm | D 16 x 25 in | D 406 x 635 mm |

Minimum Dimensions | D 0.16 x 0.05 in | D 4.06 x 1.27 mm | D 0.16 x 0.05 in | D 4.06 x 1.27 mm |

Tolerances* | +/- 0.005 in | +/- 0.127 mm | +/- 0.005 in | +/- 0.127 mm |

*Upto +/-0.0005 in( 0.0127mm),according to customer specifications

Our Post-Processing

With our Production Post-Processing Capabilities, including surface finishing, welding, and assembly, we can add value to your manufacturing projects by ensuring a high-quality finished product.

Surface Finishing*

Surface finishing is the process of improving the surface texture, appearance, and functionality of a part or component produced by CNC machining, sheet metal fabrication, or injection molding. It involves the use of various techniques to alter the surface of the part, such as polishing, sandblasting, electroplating, and painting, among others.

Welding*

Welding is a process of joining two or more pieces of metal or thermoplastic materials together by melting and fusing them to form a strong bond. In the context of CNC machining, metal fabrication, and injection molding, welding is often used to assemble and join different components or parts together to create a final product.

Assembly

Assembly refers to the process of combining multiple parts or components to create a final product. In the context of CNC machining, metal fabrication, and injection molding, assembly may involve joining different parts together using techniques such as welding, fastening, or adhesives.

50+ Material Options

Metals

Aluminum

> Light weight

> High strength

> Excellent conductivity

Price: $

Brass

> Good machinability

> High corrosion resistance

> Attractive appearance

Price: $$

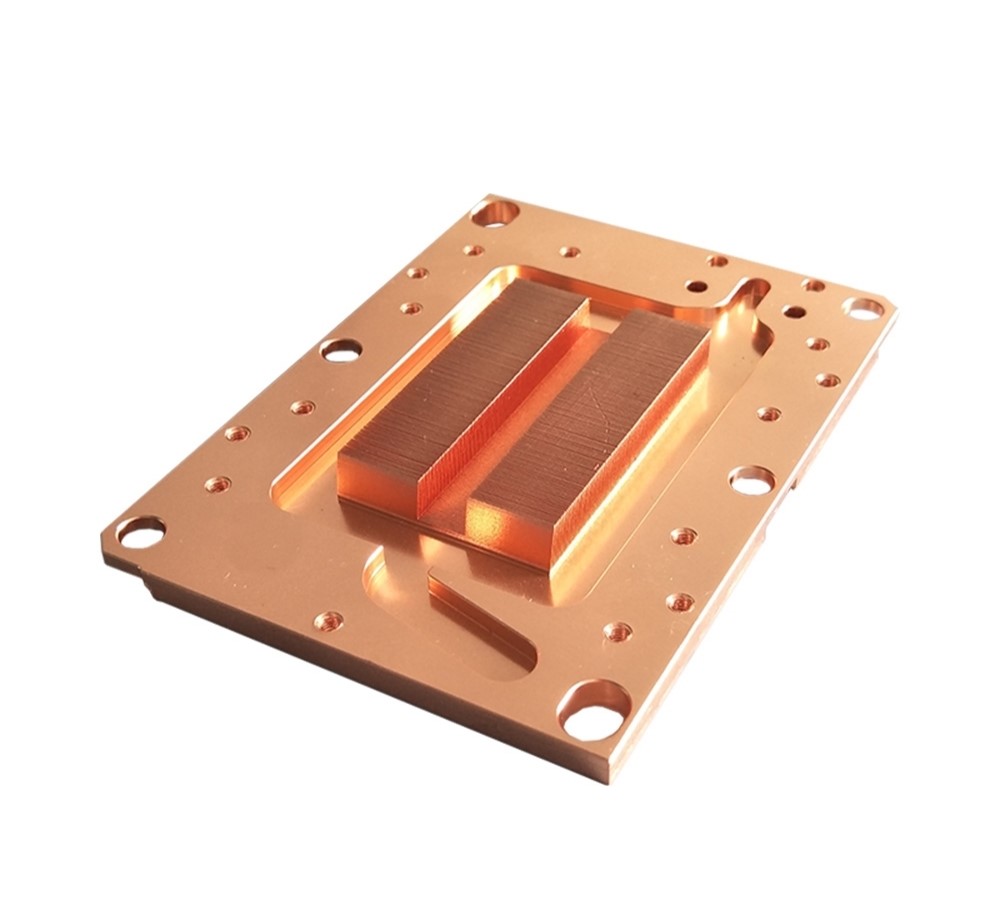

Copper

> Electrical & thermal conductivity

> High ductility

> Excellent corrosion resistance

Price: $$

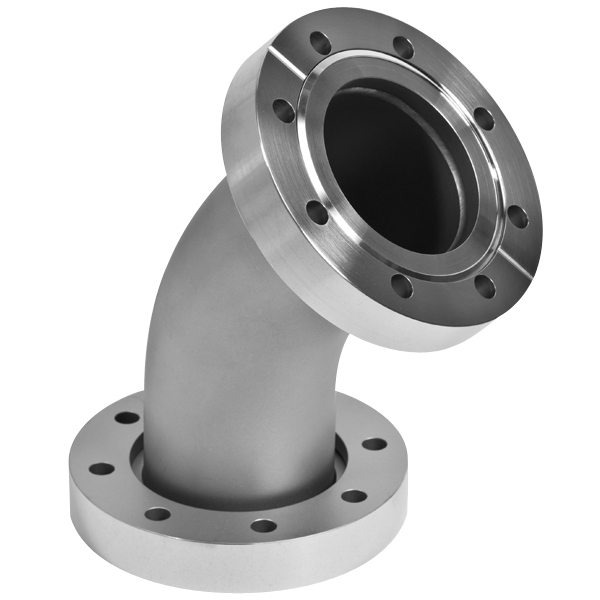

Stainless Steel

> High strength

> Durability

> Resistance to corrosion

Price: $$$

Mild steel

> Good machinability

> Availability

> Affordability

Price: $$

Tool Steel

> High hardness

> Toughness

> Wear resistance.

Price: $$$

Alloy Steel

> High strength

> Good wear resistance

> Good hardness

Price: $$$

Titanium

> High strength-to-weight ratio

> Corrosion resistance

> Biocompatibility

Price: $$$$$

Inconel

> High temperature resistance

> Corrosion resistance

> High strength

Price: $$$$$

Invar

> Dimensional stability

> Thermal stability

> Low magnetic permeability

Price: $$$$

Plastics

ABS

> Impact resistance,

> High strength-to-weight ratio,

> Ease of machining.

Price: $$

Acetal(Delrin, POM)

> High strength and stiffness

> Wear resistance

> Good dimensional stability

Price: $$

Nylon(PA)

> Strong and durable

> Lightweight

> Chemical resistance

Price: $$

PP

> Chemical resistance

> Strength and rigidity

> Cost-effectiveness

Price: $

PC

> High Impact Strength

> Good Transparency

> Thermal Stability

Price: $

PEEK

> High temperature resistance

> Chemical resistance

> Mechanical strength

Price: $$$

HDPE

> Chemical Resistance

> Impact Strength

> Wear Resistance

Price: $

PET

> Chemical resistance

> Dimensional stability

> Strength and stiffness

Price: $

Teflon(PTFE)

> Chemical resistance:

> Low coefficient of friction

> Temperature resistance

Price: $$

PVC

> Durability

> Chemical Resistance

> Cost-effectiveness

Price: $

Acrylic(PMMA)

> High optical clarity

> Good impact resistance

> Easy to machine

Price: $$

UHMW

> Wear resistance

> Low friction

> Chemical resistance

Price: $$

Surface Finishing for Machined Parts

Anodizing for Machined Aluminum Parts

Our services include anodizing for aluminum parts. Anodizing forms a durable, corrosion-resistant aluminum oxide layer through an acid and electricity-based process. This improves CNC machined aluminum parts.

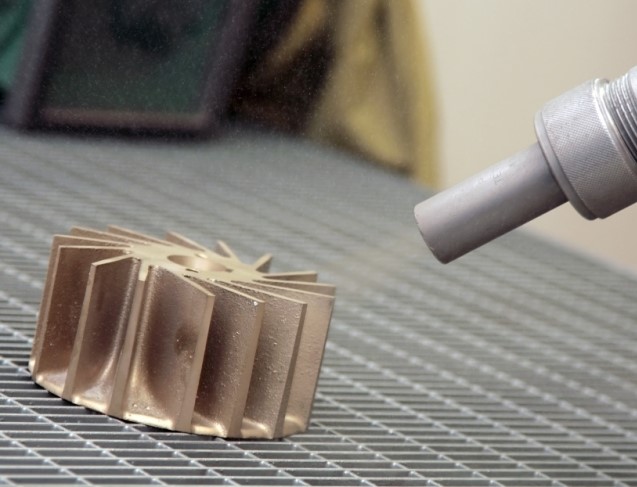

Sand Blasting in Machining

CNC machining services often employ Sand Blasting for part finishing. High-pressure fine glass beads are used in this process to enhance the surface quality of CNC machined parts.

Powder Coating for Machined Parts

Our services include powder coating for enhanced parts. This process improves appearance and durability by applying a protective finish using a resin and pigment mixture sprayed onto surfaces.

Electropolishing for Machined Parts

Improve CNC machined parts with electropolishing. This process enhances metal surfaces by creating a smoother, brighter finish. It significantly elevates both appearance and performance.

Black Oxide Coating in Machining Services

Enhance your CNC machined metal parts with black oxide coating through our services. Black oxide forms a protective surface layer through a chemical reaction, improving both appearance and durability.

Electroplating for Machined Parts

Improve your parts with electroplating in our services. Electroplating uses electric current to deposit a metal coating, enhancing the appearance and properties of CNC machined parts.

Rapid Prototyping & Production

ransform your ideas into reality with our advanced rapid prototyping technologies. Our CNC machining services, encompassing milling and turning, empower designers to swiftly and effectively bring their concepts to life. Unleash the boundless potential of your creativity with our precision services.

Lead times as short as 3 days.

Experience unparalleled precision and top-notch quality with us, a leading provider of intricate manufacturing solutions in North America. Enjoy competitive pricing and rapid turnaround times for CNC machining services. Rely on us for all your demanding manufacturing needs.

Cut costs by 20%+ without middlemen.

Why Us

High-Precision Machining

—— We invests in state-of -the-art machining equipment and technology to deliver the highest level of precision and accuracy in each project.

Experienced Team

——Our team of engineers and machinists have years of experience in the machining industry. They are highly skilled in their craft and have a deep understanding of the latest technologies, materials, and processes.

On-Time Delivery

——At Norco, we understand the importance of meeting deadlines. That’s why we have implemented efficient processes and systems to ensure that each machining project is completed on-time and to the highest quality standards.

Competitive Pricing

——We strive to offer our customers the best value for their investment. Our pricing is highly competitive, and we work closely with each customer to understand their specific needs and budget constraints.