Injection Molding Services

Norco's advanced technology and skilled team excel in mold making, plastic injection molding, and rubber molding processes.Explore our comprehensive range of injection molding services and supplies today.

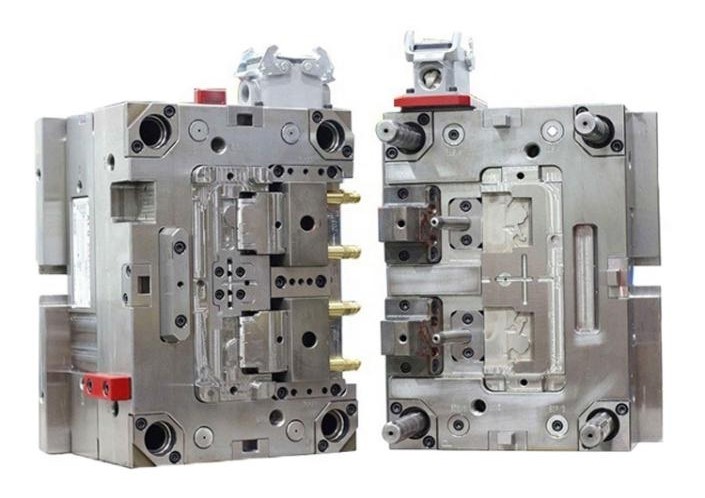

Our Injection Molding Capabilities

Discover Norco’s versatile injection molding capabilities, encompassing mold making, plastic injection molding, and rubber molding. Our seasoned team, paired with cutting-edge equipment, guarantees efficient and high-quality production, catering to diverse industry demands. Explore our comprehensive range of injection molding services and supplies to meet your unique needs.

Rubber molding is a manufacturing process that involves the production of Rubber parts using molds.

Our Injection Molding service’s Processes

Injection molding is a manufacturing process that involves injecting molten material into a mold to create a specific shape. The following are some of the key injection molding processes that we use to produce high-quality parts:

Design & Engineering

Ensure optimal functionality and manufacturability

Mold making

Material Selection

Injection Molding

Produce your parts with speed and accuracy

Quality Control

Ensure every part we produce meets your exact specifications

Finishing

Design & Engineering

Ensure optimal functionality and manufacturability

Mold making

Use the latest technology to create custom molds

Material Selection

Finishing

Provide comprehensive solutions to finish and enhance your partsa cabinet.

Quality Control

Ensure every part we produce meets your exact specifications

Injection Molding

Injection Molding Materials

Our injection molding process utilizes a wide range of materials to meet the specific needs of our customers. Some of the most common materials we use in injection molding services include:

Thermoplastics Plastics

ABS

> Impact resistance,High strength-to-weight ratio,Ease of machining.

Common types:ABS ABS-FR

Acetal(Delrin, POM)

> High strength and stiffness, Wear resistance,Good dimensional stability

Common types: POM-CPOM-HPOM-GF

Nylon(PA)

> Strong and durable, Lightweight, Chemical resistance

Common types: Nylon 6Nylon 6/6Nylon 12Nylon-GF

PC

> High Impact Strength, Good Transparency, Thermal Stability

Common types: PC PC-FR

PE

> Chemical Resistance,Impact Strength,Wear Resistance

Price: $

Common types:HDPE LDPELLDPE UHMW PE

PP

> Chemical resistance,Strength and rigidity,Cost-effectiveness

Common types:PP PP-C PP-H PP-GF

PS

>Good dimensional stability and electrical properties, High transparency, Easy to process

Common types:PS PS-HP

PET

>Chemical resistance,Dimensional stability,Strength and stiffness

Common types:PET PET-GF

PPE/PS

> High temperature resistance, Chemical resistance, Dimensional stability

Common types:PPE/PS

PEI

> High temperature resistance,High strength and stiffness, Dimensional stability

Common types:PEI PEI-GF

PPS

> High temperature resistance, Chemical resistance, Dimensional stability

Common types: PPS PPS-GF

PBT

> Dimensional stability, Electrical insulation, Heat resistance

Common types: PBT PBT-G

PMMA

>High optical clarity,Good impact resistance,Easy to machine

Common types:PMMA

PVC

>Durability,Chemical Resistance,Cost-effectiveness

Common types:PVC FPVC RPVC

PEEK

>High temperature resistance,Chemical resistance,Mechanical strength

Common types:PEEK PEEK-GF

PTFE

>Chemical resistance,Low coefficient of friction,Temperature resistance

Common types:PET PET-GF

Silicone

EPDM

Silicone Rubber

Nitrile Rubber (NBR)

> Oil and fuel resistance

> Used in automotive and industrial applications, as well as in sealing and gasketing applications

Styrene Butadiene Rubber (SBR)

>Good abrasion resistance

> Used in tire manufacturing, as well as in footwear, industrial, and automotive applications