Mold Making Service

For high-quality mold making services, look no further than our state-of-the-art equipment and materials. Our comprehensive process includes design, engineering, and machining to ensure the final product meets your unique specifications with precision and functionality.

Our Mold making Services Section

We offer high-quality mold making services to help businesses in various industries produce parts and products efficiently and accurately. Our experienced team of designers and craftsmen work together to create molds that meet our clients’ unique needs and specifications.

Custom Mold Design

Our designers use advanced software to create detailed 3D models for our mold making service. We specialize in custom mold design that accurately represents desired shapes and sizes.

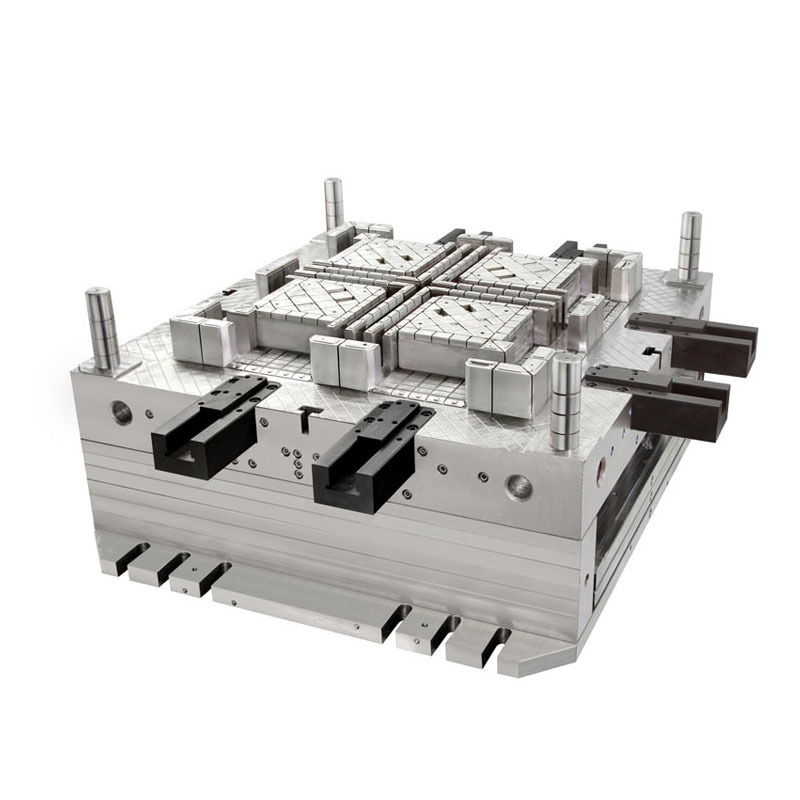

Mold Fabrication

We use advanced machinery and materials for our mold making service to fabricate molds with precision and accuracy. Our strict quality control protocols ensure molds meet exact specifications.

Design & Engineering

This process involves creating a detailed design and engineering plan for the mold. This includes determining the material for the mold, designing the mold cavity, and ensuring that the mold will function properly during the injection molding process.

Tooling

Tooling is the process of creating the mold itself. This involves using precision equipment such as CNC machines to cut and shape the mold components according to the design and engineering specifications.

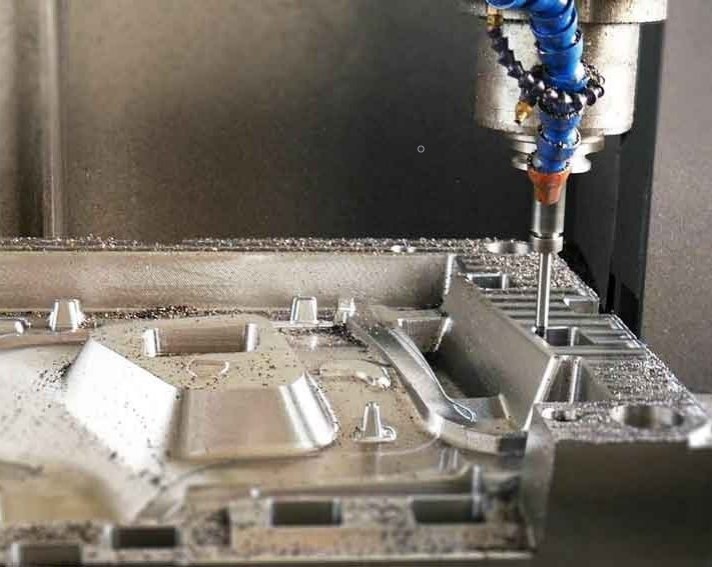

Machining

Once the mold components have been created, they must be precisely machined to ensure that they fit together perfectly. This involves using specialized tools and techniques to remove excess material and achieve the desired shape and dimensions.

Finishing

After the mold components have been machined, they may require additional finishing to ensure that they are smooth and free of defects. This may include polishing or sanding the surfaces, or applying a coating or finish.

Testing & Validation

Before the mold can be used for injection molding, it must be thoroughly tested and validated. This may involve creating sample parts and measuring their dimensions and quality, or using simulation software to predict how the mold will perform under various conditions.

Maintenance & Repair

Over time, the mold may require maintenance or repairs to keep it functioning properly. This may involve cleaning and lubricating the components, or repairing or replacing damaged or worn parts.Regular maintenance is important to ensure the longevity of the mold and the quality of the parts it produces.